◔ This product serie uses PET /PVC as the carrier and acrylic adhesive is evenly coated on both sides, and then laminated with release liner or release film. Multiple thickness available from 30μm to 325μm, mainly suitable for the bonding of labels, LCD backlight, LCD panel and other metal frames and components in digital electronics.

adhesive die-cutting adhesive tape get quote for LCD panel

1. The materials of CROWN die-cutting adhesive tape are strictly selected and their quality reaches the international packaging standards, which helps this product withstand the test of the time. There is no solvent inside the product, which causes low pollution

2. CROWN has developed many customers which are satisfied with our die-cutting adhesive tape with reliable quality assurance. The product is flame retardant and has a good peeling force

3. The product has an impeccable quality with stable performance and long service life. Made in high-end clean rooms, it has high cleanliness

4. The product is in compliance with some of the toughest quality standards across the world. It provides surface protection on goods, preventing wear and reducing scratch

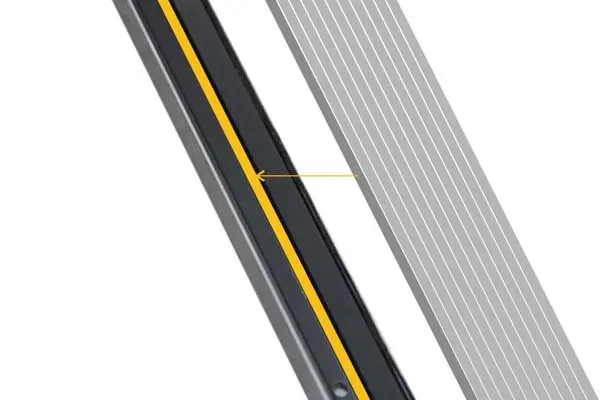

◔Flexible carrier material, strong bonding strength for curve, rough surfaces and other similar objects.

◔ Excellent heat resistance and moisture resistance property.

◔ The release liner may be customized upon customer's needs, such as brown glassine paper, white glassine paper and release film, etc.

Screen frame fixation

Suggested Model: 7983

Small amount of acrylic adhesive is coated on an ultra thin carrier, good adhesion, easy of die cutting. Suitable for the bonding of labels, LCD,backlight, LCD panels, metal frame and other components of mobile phone.

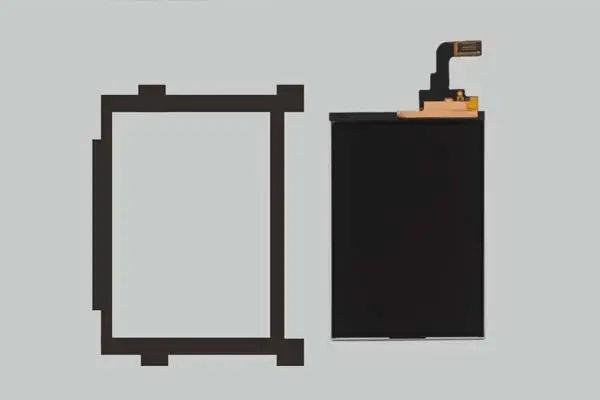

LCD Frame Fixation

Suggested Model: 7865BT

Reliable bonding effect and excellent masking effect, good bonding for LSE material. It may be used immediately after processing, wide application,such as for heavily-compressed, high-temperature or critical substances.

LED fixation

Suggested Model: 7968

Milky white double coated tape, highly stretchable. Strong adhesion and holding power.

Lens fixation

Suggested Model: 7965M

Red film as release material which enhances the die cutting application. Relatively thick adhesive layer, suitable for bonding of ABS plastic parts in cars, decorative parts of furniture, battery compartment, lens and touch screen of electronic equipment; free from degumming or bending.

| Model | Tape thickness(mic) | Color | Initial Tack(mm) | Peeling Force(N/24mm) | Holding Power(hour) | Temp. Resistance(℃) | Remarks | |||||

79(G) Serie | ||||||||||||

| 7983(G) | 30+/-5 | Transparent | <=150 | >=7 | >=24 | 120 | Ultra thin, good adhesion and excellent die cutting application on smooth surface. | |||||

| 7972(G) | 50+/-5 | Translucent | <=150 | >=8 | >=24 | 120 | Stable adhesion, good for die cutting purpose, especially suitable for foam material bonding and die cutting. | |||||

| 7980(G) | 80+/-5 | Translucent | <=120 | >=10 | >=24 | 120 | ||||||

| 7982(G) | 100+/-5 | Translucent | <=100 | >=12 | >=24 | 120 | Excellent adhesive performance for all kinds of plastic casings and foam materials; good moisture resistance. | |||||

| 7928(G) | 125+/-5 | Translucent | <=100 | >=14 | >=24 | 120 | ||||||

| 7929(G) | 140+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Excellent adhesion, suitable for the bonding of labels, panels, metal frame and other components of mobile phone. | |||||

| 7967(G) | 160+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Flexible, good adhesion of metal, plastic and other materials | |||||

| 7965(G) | 205+/-5 | Translucent | <=100 | >=17 | >=24 | 120 | ||||||

| 7926(G) | 245+/-5 | Translucent | <=100 | >=18 | >=24 | 120 | Strong adhesion; suitable for the bonding of all kinds of nameplates and membrane switch; | |||||

| 7970(G) | 225+/-5 | White | <=100 | >=16 | >=24 | 80 | PVC carrier material, suitable for the bonding of all kinds of component and decorative parts | |||||

| 7969(G) | 245+/-5 | White | <=100 | >=18 | >=24 | 80 | ||||||

| 7968(G) | 325+/-5 | White | <=100 | >=20 | >=24 | 80 | ||||||

79 Red Serie | ||||||||||||

| 7980M | 80+/-5 | Translucent | <=120 | >=10 | >=24 | 120 | Strong adhesion, flexible, suitable for the bonding of furniture accessories, metal sheets, etc. | |||||

| 7982M | 100+/-5 | Translucent | <=100 | >=12 | >=24 | 120 | ||||||

| 7967M | 160+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Strong adhesion, flexible, suitable for the bonding of automobile ABS plastic parts, accessories of furniture, metal sheets, etc. | |||||

| 7965M | 205+/-5 | Translucent | <=100 | >=17 | >=24 | 120 | ||||||

| 7965LM | 205+/-5 | Translucent | <=100 | >=18 | >=24 | 60 | ||||||

69L Serie | ||||||||||||

| 6972L | 50+/-5 | Translucent | <=180 | >=9 | >=24 | 80 | Stronger adhesion than 79 series; suitable for use on multiple kinds of materials. | |||||

| 6980L | 80+/-5 | Translucent | <=180 | >=11 | >=24 | 80 | ||||||

| 6972LE | 50+/-5 | Translucent | <=180 | >=8 | >=24 | 80 | ||||||

78BT(G) / 79TB(G) Serie | ||||||||||||

| 7880BT(G) | 80+/-5 | Black | <=120 | >=9 | >=24 | 120 | Good adhesion, excellent masking effect, suitable for the bonding of components with shading requirement | |||||

| 7882BT(G) | 100+/-5 | Black | <=100 | >=11 | >=24 | 120 | ||||||

| 7828BT(G) | 125+/-5 | Black | <=100 | >=13 | >=24 | 120 | ||||||

| 7829BT(G) | 140+/-5 | Black | <=100 | >=14 | >=24 | 120 | ||||||

| 7867BT(G) | 160+/-5 | Black | <=100 | >=14 | >=24 | 120 | ||||||

| 7865BT(G) | 205+/-5 | Black | <=100 | >=16 | >=24 | 120 | ||||||

| 7883BT(G) | 30+/-5 | Black | <=150 | >=6 | >=24 | 120 | ||||||

| 7872BT(G) | 50+/-5 | Black | <=150 | >=7 | >=24 | 120 | ||||||

Disclaimer: The product technical data are for reference only. Actual performance may differ depending on factors beyond our expectation and control. | ||||||||||||

Company Features

1. We have established a strong customer base. These customers have collaborated with us for many years and they highly trust us.

2. CROWN ADHESIVE PRODUCTS CO.,LTD. tries to manage the corporate culture in parallel with daily business operation. Get more info!