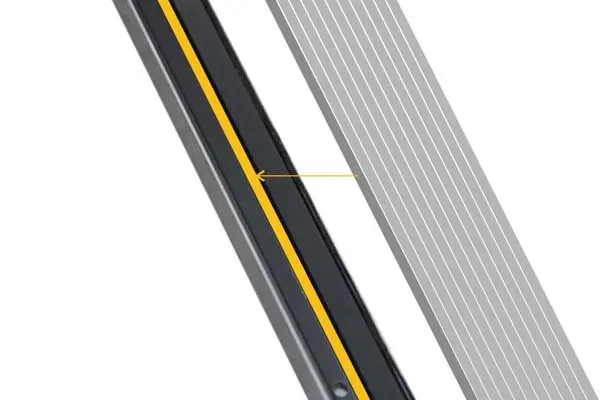

◔ This product serie uses PET /PVC as the carrier and acrylic adhesive is evenly coated on both sides, and then laminated with release liner or release film. Multiple thickness available from 30μm to 325μm, mainly suitable for the bonding of labels, LCD backlight, LCD panel and other metal frames and components in digital electronics.

CROWN pvc Film tape owner for LCD backlight

- By now, there are over staff members in our company, among which there are members in the design team, in the R&D center, and staff in the after-sales department. All of them are well-trained.

- CROWN Adhesive Tape believes credibility has a huge impact on the development. Based on customer demand, we provide excellent services for consumers with our best team resources.

- CROWN Adhesive Tape focuses on the principle of "continuous improvement on product quality" and actively conducts R&D research before production.

- For over years, we have been conducting the business of adhesive tape so that we have gathered rich customer cases and can offer various design services to satisfy customers' needs.

- We have been doing export business since our foundation and have partnered with customers from . Customers from these countries have been giving us great feedback.

1. This model of Film tape is efficient and durable thanks to the design of double sided PVC tape .

2. Our professional technicians monitor the quality of products throughout the production process, which greatly ensures the quality of products.

3. This product is widely known for its high quality and reliability.

4. Apart from the competitive price, CROWN also can supply the highest quality of Film tape.

◔Flexible carrier material, strong bonding strength for curve, rough surfaces and other similar objects.

◔ Excellent heat resistance and moisture resistance property.

◔ The release liner may be customized upon customer's needs, such as brown glassine paper, white glassine paper and release film, etc.

Screen frame fixation

Suggested Model: 7983

Small amount of acrylic adhesive is coated on an ultra thin carrier, good adhesion, easy of die cutting. Suitable for the bonding of labels, LCD,backlight, LCD panels, metal frame and other components of mobile phone.

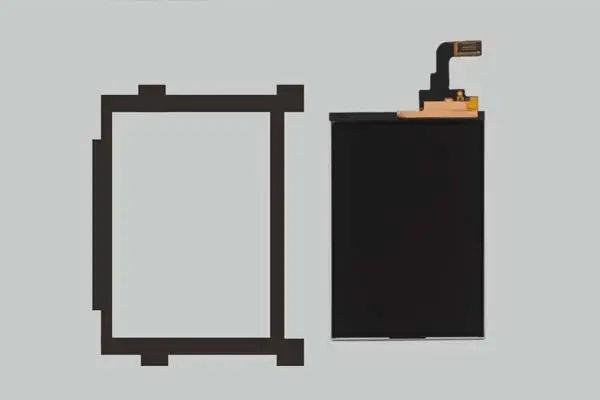

LCD Frame Fixation

Suggested Model: 7865BT

Reliable bonding effect and excellent masking effect, good bonding for LSE material. It may be used immediately after processing, wide application,such as for heavily-compressed, high-temperature or critical substances.

LED fixation

Suggested Model: 7968

Milky white double coated tape, highly stretchable. Strong adhesion and holding power.

Lens fixation

Suggested Model: 7965M

Red film as release material which enhances the die cutting application. Relatively thick adhesive layer, suitable for bonding of ABS plastic parts in cars, decorative parts of furniture, battery compartment, lens and touch screen of electronic equipment; free from degumming or bending.

| Model | Tape thickness(mic) | Color | Initial Tack(mm) | Peeling Force(N/24mm) | Holding Power(hour) | Temp. Resistance(℃) | Remarks | |||||

79(G) Serie | ||||||||||||

| 7983(G) | 30+/-5 | Transparent | <=150 | >=7 | >=24 | 120 | Ultra thin, good adhesion and excellent die cutting application on smooth surface. | |||||

| 7972(G) | 50+/-5 | Translucent | <=150 | >=8 | >=24 | 120 | Stable adhesion, good for die cutting purpose, especially suitable for foam material bonding and die cutting. | |||||

| 7980(G) | 80+/-5 | Translucent | <=120 | >=10 | >=24 | 120 | ||||||

| 7982(G) | 100+/-5 | Translucent | <=100 | >=12 | >=24 | 120 | Excellent adhesive performance for all kinds of plastic casings and foam materials; good moisture resistance. | |||||

| 7928(G) | 125+/-5 | Translucent | <=100 | >=14 | >=24 | 120 | ||||||

| 7929(G) | 140+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Excellent adhesion, suitable for the bonding of labels, panels, metal frame and other components of mobile phone. | |||||

| 7967(G) | 160+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Flexible, good adhesion of metal, plastic and other materials | |||||

| 7965(G) | 205+/-5 | Translucent | <=100 | >=17 | >=24 | 120 | ||||||

| 7926(G) | 245+/-5 | Translucent | <=100 | >=18 | >=24 | 120 | Strong adhesion; suitable for the bonding of all kinds of nameplates and membrane switch; | |||||

| 7970(G) | 225+/-5 | White | <=100 | >=16 | >=24 | 80 | PVC carrier material, suitable for the bonding of all kinds of component and decorative parts | |||||

| 7969(G) | 245+/-5 | White | <=100 | >=18 | >=24 | 80 | ||||||

| 7968(G) | 325+/-5 | White | <=100 | >=20 | >=24 | 80 | ||||||

79 Red Serie | ||||||||||||

| 7980M | 80+/-5 | Translucent | <=120 | >=10 | >=24 | 120 | Strong adhesion, flexible, suitable for the bonding of furniture accessories, metal sheets, etc. | |||||

| 7982M | 100+/-5 | Translucent | <=100 | >=12 | >=24 | 120 | ||||||

| 7967M | 160+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Strong adhesion, flexible, suitable for the bonding of automobile ABS plastic parts, accessories of furniture, metal sheets, etc. | |||||

| 7965M | 205+/-5 | Translucent | <=100 | >=17 | >=24 | 120 | ||||||

| 7965LM | 205+/-5 | Translucent | <=100 | >=18 | >=24 | 60 | ||||||

69L Serie | ||||||||||||

| 6972L | 50+/-5 | Translucent | <=180 | >=9 | >=24 | 80 | Stronger adhesion than 79 series; suitable for use on multiple kinds of materials. | |||||

| 6980L | 80+/-5 | Translucent | <=180 | >=11 | >=24 | 80 | ||||||

| 6972LE | 50+/-5 | Translucent | <=180 | >=8 | >=24 | 80 | ||||||

78BT(G) / 79TB(G) Serie | ||||||||||||

| 7880BT(G) | 80+/-5 | Black | <=120 | >=9 | >=24 | 120 | Good adhesion, excellent masking effect, suitable for the bonding of components with shading requirement | |||||

| 7882BT(G) | 100+/-5 | Black | <=100 | >=11 | >=24 | 120 | ||||||

| 7828BT(G) | 125+/-5 | Black | <=100 | >=13 | >=24 | 120 | ||||||

| 7829BT(G) | 140+/-5 | Black | <=100 | >=14 | >=24 | 120 | ||||||

| 7867BT(G) | 160+/-5 | Black | <=100 | >=14 | >=24 | 120 | ||||||

| 7865BT(G) | 205+/-5 | Black | <=100 | >=16 | >=24 | 120 | ||||||

| 7883BT(G) | 30+/-5 | Black | <=150 | >=6 | >=24 | 120 | ||||||

| 7872BT(G) | 50+/-5 | Black | <=150 | >=7 | >=24 | 120 | ||||||

Disclaimer: The product technical data are for reference only. Actual performance may differ depending on factors beyond our expectation and control. | ||||||||||||

Company Features

1. Since its establishment, CROWN ADHESIVE PRODUCTS CO.,LTD. has been a competitive manufacturer of double sided PVC tape . We have earned a good reputation in the world.

2. Technology from CROWN ADHESIVE PRODUCTS CO.,LTD. has reached international advanced level.

3. With the tenet of die cut double sided tape , we are striving for the top-ranking brand. Inquire now! It is a fact that CROWN has been keeping the idea of Film tape first in mind since founded. Inquire now! CROWN has been striving to achieve to be the leading PVC tape manufacturer. Inquire now! CROWN gets wide trusts and respect for excellent double sided PET tape and double sided film tape. Inquire now!