◔ This product serie uses PE/EVA foam as carrier and acrylic adhesive/hot melt adhesive is evenly coated on both sides, and then laminated with release liner or release film. It has excellent weather resistance, cushioning effect, air tightness, unlikely to rebound, hence widely used in the bonding of digital electronics parts, household appliance, automobile parts, and other industries.

good cushioning effect double sided foam tape tape bulk production for household appliance

1. double sided foam tape from CROWN ADHESIVE PRODUCTS CO.,LTD. conveys unique innovative product concept.

2. It has good touch comfort properties. It has been tested in terms of mechanical & surface properties associated with the hand feel and performs well in the results.

3. The product has high seaming quality. It does not have broken stitches, miss stitches, and skipping stitches that may all lead to loose thread and poor seam quality.

4. This product provides an array of cost and sustainability benefits – it allows air to flow through and ventilate the building, permits visibility from the inside and deflects Solar Heat Gain.

◔Strong and reliable bonding strength

◔ Good flexibility, suitable for structural surface bonding

◔Good filler feature, effective filler of visible gaps

◔ Good cushioning effect, UV resistance and anti-aging

Smartphone Camera Bonding

Suggested Model: WP03015

Ultra thin with only 0.15 mm thickness, individual closed cell PE foam structure enables dust proof and bonding strength, waterproof feature is up to the international IPX7 standard, perfect suitable for mobile phone development.

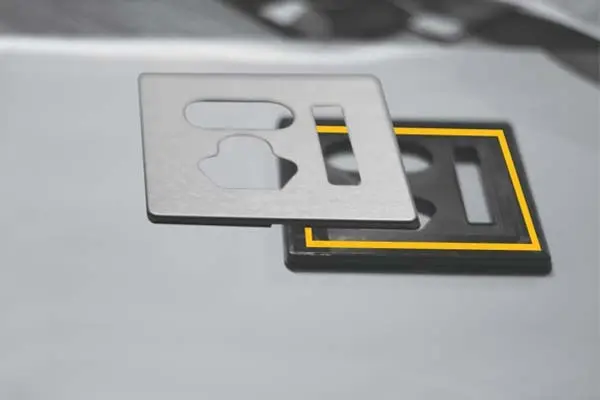

Power socket panel bonding and fixation

Suggested Model: DP0302B

Ultra thin with only 0.2mm thickness, good flexibility, cushioning and filler effects; impact resistance; easy to use and suitable for punching application.

Electric oven glass panel bonding and fixation

Suggested Model: DP0303W

0.m thick, good filler effect, good cushioning and impact absorption effect.

Kettle switch bonding and fixation

Suggested Model: DP1005B

Impact resistance; good filler effect, easy to use and suitable for punching application.

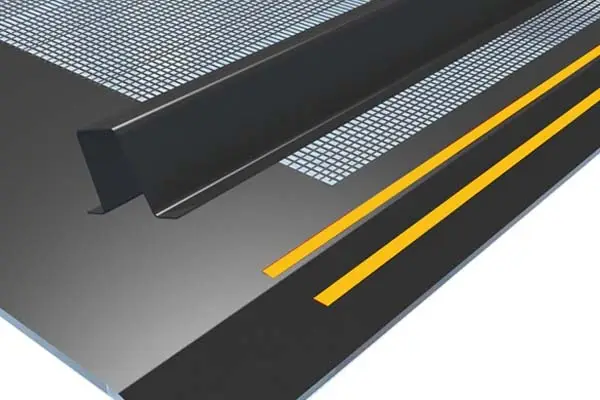

Car door sealer lining bonding and fixation

Suggested Model: DP1008BR

Impact resistance; good filler effect, easy to use and suitable for punching application.

| Model | Carrier | Tape thickness(mic) | Color | Initial Tack(mm) | Peeling Force(N/24mm) | Holding Power(hour) | Temp. Resistance(℃) | Remarks | |||||

Waterproof PE foam Serie | |||||||||||||

| WP03015B | PE, density 300kg/m3 | 150+/-20 | Black | <=250 | >=10 or damaged on the steel panel | >=24 | 100 | Waterproof foam, good for processing application, support die cutting into narrow frames for waterproof structure use. | |||||

| WP03020B | PE, density 300kg/m3 | 200+/-30 | Black | <=250 | >=12 or damaged on the steel panel | >=24 | 80 | ||||||

| WP03025B | PE, density 300kg/m3 | 250+/-30 | Black | <=250 | >=12 or damaged on the steel panel | >=24 | 80 | Waterproof foam, suitable for the bonding of nameplates and decorating parts with waterproof requirements.cture use. | |||||

| WP03030B | PE, density 300kg/m3 | 300+/-30 | Black | <=250 | >=12 or damaged on the steel panel | >=24 | 80 | ||||||

| High-density PE foam Serie | |||||||||||||

| DP0301B | PE, density 300kg/m3 | 200+/-30 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Ultra thin, suitable for light load bonding application, such as signs and nameplates | |||||

| DP0302B | PE, density 300kg/m3 | 230+/-30 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | ||||||

| DP1002B | PE, density 100kg/m3 | 300+/-30 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Good flexibility, suitable for bonding of signs and decorating parts. | |||||

| DP1003B | PE, density 100kg/m3 | 400+/-50 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | ||||||

| DP1004B | PE, density 100kg/m3 | 500+/-50 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Suitable for the bonding of all kinds of signs and decorative parts. | |||||

| DP1005BR | PE, density 100kg/m3 | 600+/-50 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Red release film, suitable for the bonding of all kinds of signs and decorating parts. | |||||

| DP1008B | PE, density 100kg/m3 | 900+/-50 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| DP1010B | PE, density 100kg/m3 | 1000+/-100 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | ||||||

| DP1010WR | PE, density 100kg/m3 | 1000+/-100 | White | <=50 | Damaged on the steel panel | >=24 | 80 | White carrier, suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| DP1508FR | PE, density 65kg/m3 | 900+/-50 | Grey | <=50 | Damaged on the steel panel | >=24 | 80 | Red release film, suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| DP1510BG | PE, density 65kg/m3 | 1000+/-100 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Green release film, suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| DP1520B | PE, density 65kg/m3 | 2000+/-100 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| DP1530BG | PE, density 65kg/m3 | 3000+/-100 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Green release film, suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| Low-density PE foam Serie | |||||||||||||

| GP1205B | PE, density 83kg/m3 | 600+/-50 | Black | <=100 | Damaged on the steel panel | >=2 | - | Suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| GP1210W | PE, density 83kg/m3 | 1100+/-50 | White | <=100 | Damaged on the steel panel | >=2 | - | ||||||

| GP1210BR | PE, density 83kg/m3 | 1100+/-50 | Black | <=100 | Damaged on the steel panel | >=2 | - | ||||||

| GP1810B | PE, density 58kg/m3 | 1100+/-100 | Black | <=100 | Damaged on the steel panel | >=2 | - | ||||||

| GP1810WR | PE, density 58kg/m3 | 1100+/-100 | White | <=100 | Damaged on the steel panel | >=2 | - | ||||||

| GP2010B | PE, density 53kg/m3 | 1100+/-100 | Black | <=100 | Damaged on the steel panel | >=2 | - | ||||||

Hot Melt Adhesive PE/EVA foam Serie | |||||||||||||

| HP2010B | PE, density 53kg/m3 | 1100+/-100 | Black | <=200 | Damaged on the steel panel | >=10min | - | General purpose adhesive tape that is used for components mounting of household appliances, furniture, automobiles, etc. | |||||

| HP2010BR | PE, density 53kg/m3 | 1100+/-100 | Black | <=200 | Damaged on the steel panel | >=10min | - | ||||||

| HE3810W | EVA, density 80kg/m3 | 1100+/-100 | White | <=200 | Damaged on the steel panel | >=10min | - | ||||||

| HE3815W | EVA, density 80kg/m3 | 1600+/-100 | White | <=200 | Damaged on the steel panel | >=10min | - | ||||||

| HE3820W | EVA, density 80kg/m3 | 2100+/-100 | White | <=200 | Damaged on the steel panel | >=10min | - | ||||||

| HP4020W | EVA, density 20kg/m3 | 2100+/-100 | White | <=200 | Damaged on the steel panel | >=10min | - | ||||||

| HP4025W | EVA, density 20kg/m3 | 2600+/-100 | White | <=200 | Damaged on the steel panel | >=10min | - | ||||||

Note: 1."B" means the carrier color is Black, "W" means the carrier color is white, "R" means the release liner is 65mic red release film,"G" means the release liner is 65mic green release film, "L" means the release liner is 65mic blue release film. Other is white release liner. 2.The product technical data are for reference only. Actual performance may differ depending on factors beyond our expectation and control | |||||||||||||

Company Features

1. CROWN ADHESIVE PRODUCTS CO.,LTD. is a professional lighting company integrating design, development, production, sales and engineering.

2. We have explored new overseas markets in recent years, mainly including USA, Russia, New Zealand, and so on. We have grown bigger because of continuous products innovation and quality products that we have offered to these customers.

3. We promise we will never compete or business unfairly. All of our business activities are conducted on the basis of legitimacy and righteousness. In doing so, we hope to cultivate a fair, equal, and nonmalignant business environment. Under the principle of win-win cooperation, we always working hard to seek for long term partnership with all our customers. We will allow our customers to engage with the business and strengthen interaction with them about the product and services. Through this way, we can incentivize them to keep coming back. We have made a feasible goal: to increase the profit margin through product innovation. Except for the development of new products, we will improve the performance of the existing products based on customers' needs. We work with ISO-certified suppliers who have the right working conditions, working times, and who conduct their work without undue risk or pressure.