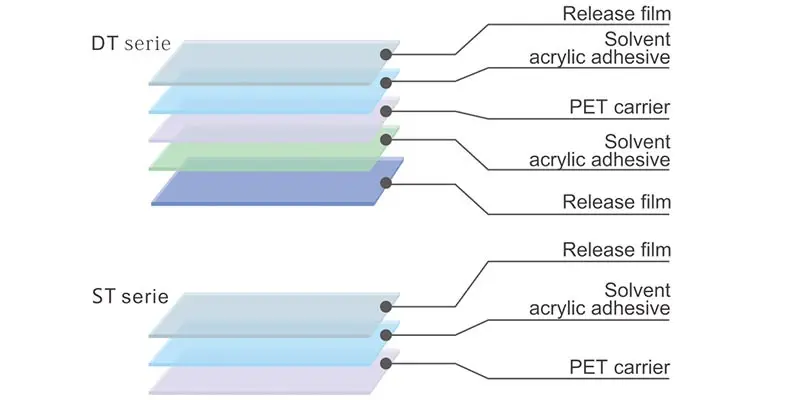

◔ This product series uses thin PET as the carrier and acrylic adhesive is evenly coated on single or double sides, and laminated with release film. It is mainly used for the bonding of graphite sheet in smart phones.

High-quality black thin tape factory

◔Coated in class 1,000 cleanroom ensures high product cleanliness.

◔ Ultra-thin design, high tensile strength, good electrical insulation, low thermal resistance

◔ Good resistance to high and low temperature, good weather resistance, warping resistance, good affinity to the target object

◔ Special design may be added upon customers’ requests, such as surface fingerprint prevention

Surface protection of graphite sheet

Suggested Model: ST7600 / ST3601SB

Ultra-thin single coated tape, stable adhesion, mainly used in surface protection and decoration of graphite pieces and other materials. Good masking effect for some small flaws.

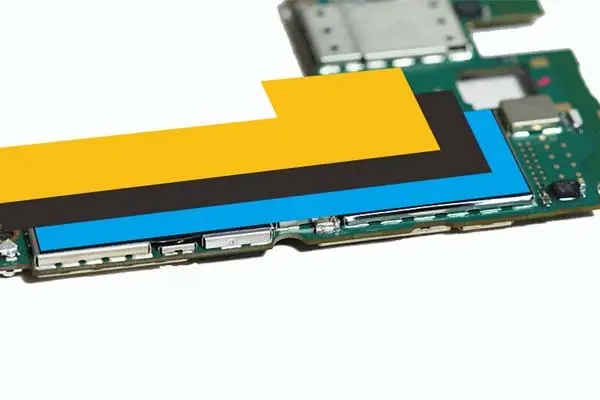

Fixation of graphite sheet

Suggested Model: DT7600 / DT7601SB

Ultra thin design, beneficial to reduce the thickness of electronic equipment, suitable for the bonding of all kinds of components in limited space, especially the bonding between graphite sheets in the smart phone and the bonding between graphite sheet and mobile phone components.

Headphone line wrapping and fixation

Suggested Model: DT7603

Ultra thin design, special acrylic adhesive used. Strong adhesion to all kinds of materials; anti-rebound, quite suitable for places with anti-rebound requirements, such as the bonding of headset wire/ data cable wrapping membrane; stable and reliable bonding; transparent, improving packaging appearance.

| Model | Tape thickness(mic) | Color | Initial Tack(mm) | Peeling Force(N/24mm) | Holding Power(hour) | Remarks | ||||||

Single coated Serie | ||||||||||||

| ST7600 | 5-7 | Transparent | >180 | >4 | >=24 | Ultra thin, stable adhesion, mainly used in surface protection of graphite sheets | ||||||

| ST7601 | 10+/-2 | Transparent | >180 | >6 | >=24 | Stable adhesion, mainly used in surface protection of graphite sheet | ||||||

| ST7602 | 20+/-2 | Transparent | >180 | >6 | >=24 | Strong adhesion, mainly used in surface protection of graphite sheet and other materials. | ||||||

| ST7603 | 30+/-3 | Transparent | >180 | >8 | >=24 | |||||||

| ST7600F | 7+/-1 | Black | >180 | >3 | - | Matte fingerprint proof surface, ultrathin, mainly used in surface protection of graphite sheets | ||||||

| ST7601F | 12+/-2 | Black | >180 | >6 | - | Matte fingerprint proof surface, mainly used in surface protection of graphite sheets | ||||||

| ST7603F | 30+/-3 | Black | >180 | >8 | >=24 | Matte fingerprint proof surface, suitable for surface protection of graphite sheet and other materials | ||||||

| ST7603W | 30+/-3 | White | >180 | >8 | >=24 | White, suitable for surface protection of graphite sheet and other materials | ||||||

| ST7603WF | 30+/-3 | White | >180 | >8 | >=24 | White, matte fingerprint proof surface, suitable for surface protection of graphite sheet and other materials | ||||||

| ST3601SB | 10+/-1 | Black | >180 | 4.5-7.5 | >=24 | Black, semi-transparent, mainly used in surface protection of graphite sheets | ||||||

| ST7601SB | 10+/-1 | Black | >180 | >5 | >=24 | |||||||

| ST7602B | 20+/-2 | Black | >180 | >6 | >=24 | Black, suitable for surface protection of graphite sheet and other materials, with masking effect | ||||||

| ST7603B | 30+/-3 | Black | >180 | >8 | >=24 | |||||||

| ST7605B | 50+/-3 | Black | >180 | >12 | >=24 | |||||||

| ST7604W | 40+/-2 | White | >180 | >8 | >=24 | White, suitable for surface protection of graphite sheet and other materials | ||||||

Double coated Serie | ||||||||||||

| DT7600 | 7+/-1 | Transparent | >180 | >6 | >=24 | Ultra thin design, suitable for the bonding of all kinds of components with thickness restriction, such as bonding of graphite sheet | ||||||

| DT7601 | 10+/-1 | Transparent | >180 | >10 | >=24 | Suitable for the bonding of all kinds of components with thickness restriction, such as bonding of graphite sheet | ||||||

| DT7602 | 20+/-2 | Transparent | >180 | >12 | >=24 | Mainly for bonding of graphite sheet and other materials in the smart phone industry | ||||||

| DT7603 | 30+/-3 | Transparent | >180 | >13 | >=24 | High adhesion, strong adhesion on plastic film and model products, such as the bonding of headphone line wrap film, etc. | ||||||

| DT7604 | 40+/-3 | Transparent | >180 | >14 | >=24 | Used in fixation of LCD peripheral sheets, backlight module components, FPC and others of smart phones. | ||||||

| DT7605 | 50+/-4 | Transparent | >180 | >15 | >=24 | |||||||

| DT7608 | 80+/-5 | Transparent | >180 | >18 | >=24 | Used in the bonding and fixation of components of smart phones. | ||||||

| DT7610 | 100+/-8 | Transparent | >180 | >25 | >=24 | Strong adhesion; suitable for the bonding of multiple kinds of electronic spare parts | ||||||

| DT7600SB | 7+/-1 | Black | >180 | >4 | >=24 | Black semi-transparent, ultra thin, suitable for the bonding of all kinds of components with thickness restriction, such as bonding between graphite sheets and between the graphite sheet and other components | ||||||

| DT7601SB | 15+/-1 | Black | >180 | >10 | >=24 | |||||||

| DT7602SB | 20+/-2 | Black | >180 | >12.5 | >=24 | |||||||

| DT7603B | 30+/-3 | Black | >180 | >13 | >=24 | Black, mainly for bonding of graphite sheet and other cooling fin in the smart phone industry | ||||||

| DT7604B | 40+/-4 | Black | >180 | >13 | >=24 | Black, used in the fixation of graphite sheet, LCD peripheral sheets, backlight module components of smart phone; having certain masking effect | ||||||

| DT7605B | 50+/-5 | Black | >180 | >15 | >=24 | |||||||

Disclaimer: The product technical data are for reference only. Actual performance may differ depending on factors beyond our expectation and control. | ||||||||||||