◔ This product serie is directly coated with acrylic adhesive on the release liner without any carrier. The tape is transparent in color, has excellent bonding effect, preventing residues, oozing and other defects. It is good for punching and die cutting applications; widely used in general industrial assembly, bonding of membrane switch, nameplates and electronic parts.

New adhesive transfer tape carrier bulk production for electronic parts

1. CROWN adhesive transfer tape is designed in an aesthetically pleasing way. The product is popular for its moisture resistance property

2. CROWN ADHESIVE PRODUCTS CO.,LTD. has won customers' trust and support with excellent sales, perfect design, excellent production and sincere services. The product is characterized by good aging resistance

3. The product is featured by the first - class quality and stable performance. It is made of hard adhesives that are not easy to squeeze out

◔Anti-rebound, resistance to warping, heat resistance and temperature resistance

◔ Highly transparent

◔ Strong adhesion and holding power

◔ Good bonding effect to multiple kinds of carrier materials

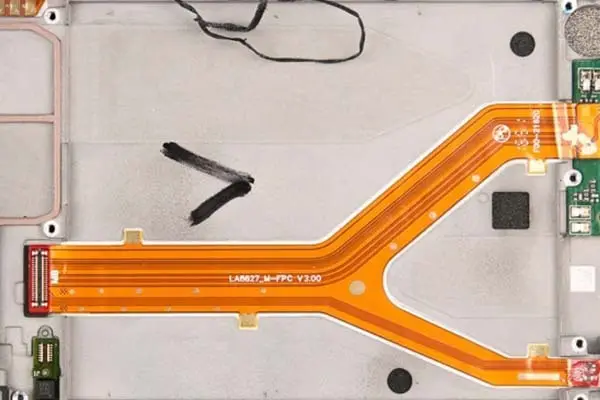

FPC bonding and fixation

Suggested Model: NC767

This model is 50 ~ 55μm thick, dry texture, good for punching and die cutting application; stable bonding effect to all kinds of carrier materials; good bonding to FPC.

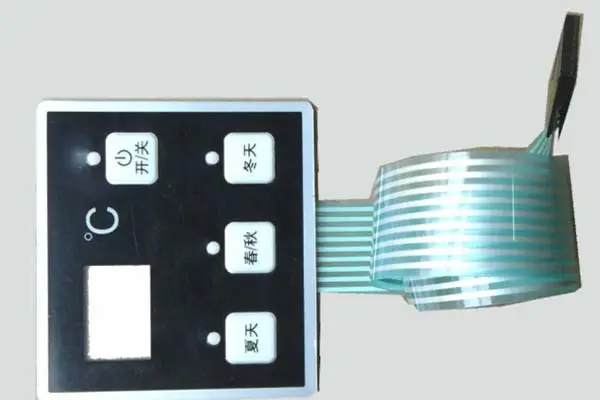

Membrane switch bonding

Suggested Model: NC768

Relatively dry texture, good for punching and die cutting application; stable bonding effect to all kinds of carrier materials, such as membrane, plastics or metal.

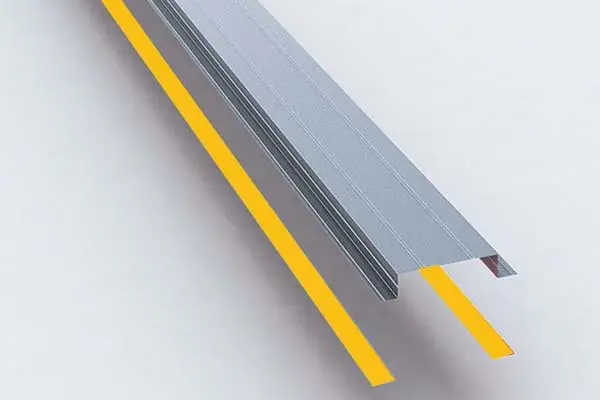

Metal sheet temporary bonding and fixation

Suggested Model: NC768A

This model is 128 ~132μm thick and relatively soft, strong bonding effect, especially suitable for the bonding of foam materials.

Model | Tape thickness(mic) | Color | Initial Tack(mm) | Peeling Force(N/24mm) | Holding Power(hour) | Temp. Resistance(℃) | Remarks | |||||

| NC767 | 50-55 | Transparent | >=50 | >=10 | >=24 | 80 | White release liner, relatively hard texture, suitable for die-cutting and punching. | |||||

| NC767N | 50-55 | Transparent | <=100 | >=10 | >=24 | 80 | Yellow kraft paper, good initial tack, suitable for the bonding of all kinds of plastic and metal panels. | |||||

| NC768 | 128-132 | Transparent | <=150 | >=13 | >=24 | 80 | White release liner, relatively dry, good film-forming property, suitable for die-cutting and punching. | |||||

| NC768N | 128-132 | Transparent | <=100 | >=13 | >=24 | 80 | Yellow kraft paper, good initial tack, suitable for the bonding of all kinds of plastic and metal panels. | |||||

| NC767G | 50-55 | Transparent | <=100 | >=11 | >=24 | 80 | White release liner, suitable for the bonding of all kinds of plastic and foam materials. | |||||

| NC767A | 50-55 | Transparent | <=100 | >=11 | >=24 | 80 | White release liner, strong adhesion, suitable for the bonding of all kinds of plastic and foam materials. | |||||

| NC768A | 128-132 | Transparent | <=150 | >=14 | >=24 | 80 | White release liner, strong adhesion, suitable for the bonding of all kinds of plastic and foam materials. | |||||

| NC767G-1 | 50-55 | Transparent | <=100 | >=9 | >=24 | 80 | White release liner, relatively hard texture, suitable for die-cutting and punching. | |||||

Disclaimer: The product technical data are for reference only. Actual performance may differ depending on factors beyond our expectation and control. | ||||||||||||

Company Features

1. CROWN ADHESIVE PRODUCTS CO.,LTD. has long been focused on the R&D and manufacture of adhesive transfer tape . There's a strict and complete quality management system to guarantee the quality of transfer tape.

2. The plant of CROWN has advanced machines and professional testing equipment.

3. CROWN ADHESIVE PRODUCTS CO.,LTD. has made a great progress in double sided transfer tape development thanks to its professional R&D base. The goal of our company is to become an innovative and distinctive manufacturing company. We will invest more in introducing advanced and high-tech manufacturing and developing facilities which can help us to broaden our product range.