◔ This product serie uses PE/EVA foam as carrier and acrylic adhesive/hot melt adhesive is evenly coated on both sides, and then laminated with release liner or release film. It has excellent weather resistance, cushioning effect, air tightness, unlikely to rebound, hence widely used in the bonding of digital electronics parts, household appliance, automobile parts, and other industries.

PE/EVA Foam Adhesive Tape, Adhesive Foam Tape1

1. The technology used to manufacture CROWN double sided foam tape is innovative and advanced, ensuring standardization production.

2. This product has reliable quality and stable performance.

3. In the aspect of its quality, it has been tested for many times with the help of our professional team.

4. CROWN have become the preferred brand for many costumers with its excellent quality, perfect service and competitive price.

◔Strong and reliable bonding strength

◔ Good flexibility, suitable for structural surface bonding

◔Good filler feature, effective filler of visible gaps

◔ Good cushioning effect, UV resistance and anti-aging

Smartphone Camera Bonding

Suggested Model: WP03015

Ultra thin with only 0.15 mm thickness, individual closed cell PE foam structure enables dust proof and bonding strength, waterproof feature is up to the international IPX7 standard, perfect suitable for mobile phone development.

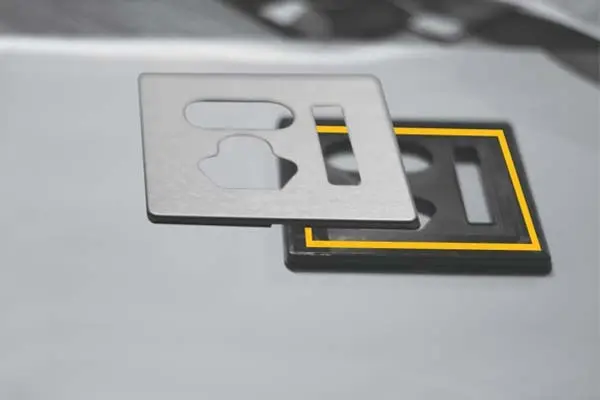

Power socket panel bonding and fixation

Suggested Model: DP0302B

Ultra thin with only 0.2mm thickness, good flexibility, cushioning and filler effects; impact resistance; easy to use and suitable for punching application.

Electric oven glass panel bonding and fixation

Suggested Model: DP0303W

0.m thick, good filler effect, good cushioning and impact absorption effect.

Kettle switch bonding and fixation

Suggested Model: DP1005B

Impact resistance; good filler effect, easy to use and suitable for punching application.

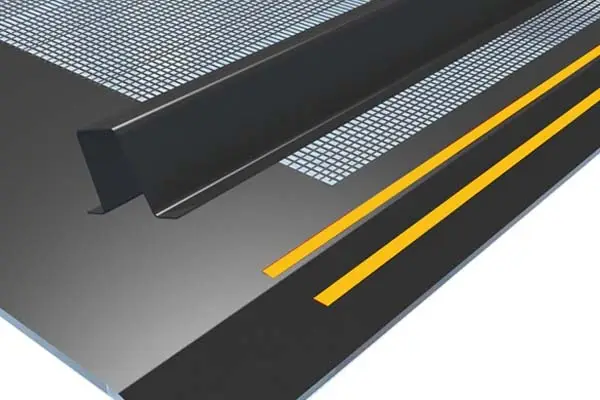

Car door sealer lining bonding and fixation

Suggested Model: DP1008BR

Impact resistance; good filler effect, easy to use and suitable for punching application.

| Model | Carrier | Tape thickness(mic) | Color | Initial Tack(mm) | Peeling Force(N/24mm) | Holding Power(hour) | Temp. Resistance(℃) | Remarks | |||||

Waterproof PE foam Serie | |||||||||||||

| WP03015B | PE, density 300kg/m3 | 150+/-20 | Black | <=250 | >=10 or damaged on the steel panel | >=24 | 100 | Waterproof foam, good for processing application, support die cutting into narrow frames for waterproof structure use. | |||||

| WP03020B | PE, density 300kg/m3 | 200+/-30 | Black | <=250 | >=12 or damaged on the steel panel | >=24 | 80 | ||||||

| WP03025B | PE, density 300kg/m3 | 250+/-30 | Black | <=250 | >=12 or damaged on the steel panel | >=24 | 80 | Waterproof foam, suitable for the bonding of nameplates and decorating parts with waterproof requirements.cture use. | |||||

| WP03030B | PE, density 300kg/m3 | 300+/-30 | Black | <=250 | >=12 or damaged on the steel panel | >=24 | 80 | ||||||

| High-density PE foam Serie | |||||||||||||

| DP0301B | PE, density 300kg/m3 | 200+/-30 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Ultra thin, suitable for light load bonding application, such as signs and nameplates | |||||

| DP0302B | PE, density 300kg/m3 | 230+/-30 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | ||||||

| DP1002B | PE, density 100kg/m3 | 300+/-30 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Good flexibility, suitable for bonding of signs and decorating parts. | |||||

| DP1003B | PE, density 100kg/m3 | 400+/-50 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | ||||||

| DP1004B | PE, density 100kg/m3 | 500+/-50 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Suitable for the bonding of all kinds of signs and decorative parts. | |||||

| DP1005BR | PE, density 100kg/m3 | 600+/-50 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Red release film, suitable for the bonding of all kinds of signs and decorating parts. | |||||

| DP1008B | PE, density 100kg/m3 | 900+/-50 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| DP1010B | PE, density 100kg/m3 | 1000+/-100 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | ||||||

| DP1010WR | PE, density 100kg/m3 | 1000+/-100 | White | <=50 | Damaged on the steel panel | >=24 | 80 | White carrier, suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| DP1508FR | PE, density 65kg/m3 | 900+/-50 | Grey | <=50 | Damaged on the steel panel | >=24 | 80 | Red release film, suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| DP1510BG | PE, density 65kg/m3 | 1000+/-100 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Green release film, suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| DP1520B | PE, density 65kg/m3 | 2000+/-100 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| DP1530BG | PE, density 65kg/m3 | 3000+/-100 | Black | <=50 | Damaged on the steel panel | >=24 | 80 | Green release film, suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| Low-density PE foam Serie | |||||||||||||

| GP1205B | PE, density 83kg/m3 | 600+/-50 | Black | <=100 | Damaged on the steel panel | >=2 | - | Suitable for the bonding of all kinds of nameplates and decorating parts. | |||||

| GP1210W | PE, density 83kg/m3 | 1100+/-50 | White | <=100 | Damaged on the steel panel | >=2 | - | ||||||

| GP1210BR | PE, density 83kg/m3 | 1100+/-50 | Black | <=100 | Damaged on the steel panel | >=2 | - | ||||||

| GP1810B | PE, density 58kg/m3 | 1100+/-100 | Black | <=100 | Damaged on the steel panel | >=2 | - | ||||||

| GP1810WR | PE, density 58kg/m3 | 1100+/-100 | White | <=100 | Damaged on the steel panel | >=2 | - | ||||||

| GP2010B | PE, density 53kg/m3 | 1100+/-100 | Black | <=100 | Damaged on the steel panel | >=2 | - | ||||||

Hot Melt Adhesive PE/EVA foam Serie | |||||||||||||

| HP2010B | PE, density 53kg/m3 | 1100+/-100 | Black | <=200 | Damaged on the steel panel | >=10min | - | General purpose adhesive tape that is used for components mounting of household appliances, furniture, automobiles, etc. | |||||

| HP2010BR | PE, density 53kg/m3 | 1100+/-100 | Black | <=200 | Damaged on the steel panel | >=10min | - | ||||||

| HE3810W | EVA, density 80kg/m3 | 1100+/-100 | White | <=200 | Damaged on the steel panel | >=10min | - | ||||||

| HE3815W | EVA, density 80kg/m3 | 1600+/-100 | White | <=200 | Damaged on the steel panel | >=10min | - | ||||||

| HE3820W | EVA, density 80kg/m3 | 2100+/-100 | White | <=200 | Damaged on the steel panel | >=10min | - | ||||||

| HP4020W | EVA, density 20kg/m3 | 2100+/-100 | White | <=200 | Damaged on the steel panel | >=10min | - | ||||||

| HP4025W | EVA, density 20kg/m3 | 2600+/-100 | White | <=200 | Damaged on the steel panel | >=10min | - | ||||||

Note: 1."B" means the carrier color is Black, "W" means the carrier color is white, "R" means the release liner is 65mic red release film,"G" means the release liner is 65mic green release film, "L" means the release liner is 65mic blue release film. Other is white release liner. 2.The product technical data are for reference only. Actual performance may differ depending on factors beyond our expectation and control | |||||||||||||

Company Features

1. CROWN ADHESIVE PRODUCTS CO.,LTD. is a leading multinational manufacturer of double sided foam tape .

2. You can fully rely on our high-end technology to produce best quality of double coated tape .

3. Since its inception, CROWN ADHESIVE PRODUCTS CO.,LTD. has been adhering to the 'sustainable innovation, the pursuit of excellence' spirit of enterprise. Get quote! CROWN ADHESIVE PRODUCTS CO.,LTD. firmly sticks to customer's needs to improve EVA foam tape. Get quote! CROWN believes that ever-improving quality of service and competitive price of adhesive foam tape will be the best choice for the development of CROWN. Get quote! CROWN ADHESIVE PRODUCTS CO.,LTD. upholds the true needs to every customer and aims to produce perfect PE foam tape . Get quote!

1mm thick double side PE foam acrylic insulation tape

Backing | PE foam | |||

Adhesive | Acrylic adhesive | |||

Color | White, Gray, Black | |||

Usage | Widely used in automotive interior and exterior components, signs, nameplates and other fixing and bonding | |||

Feature | 1, High shear strength gives high load bearing ability. 2, Composite die-cuts easily. 3, Good combination of flexibility and conformability with strength & wear resistance. 4 Good durability designed for permanent bonding 5 Variable thickness from 0.5mm to 2mm 6 Size 1020mm(width) X 50m(length) or customized size | |||

Advantage | A. Trading & Factory Supplier since 2004 B. ISO 9001, ROHS, SGS certified for exports C. Complete Industry Chain from R&D, production to sales D. Shanghai Location best for international trade E. Perfect service available 24/7 | |||

Application | I. General mounting of mirrors, signs, nameplates, hooks, soap dispensers and reflectors. II. Filling and sealing gaps around windows, doors, and car/SUV tops for better insulation. III. Gasketing, cushioning, vibration control in speakers, vehicles, electronic components, and frames. IV. Apply to permanent fixing, irregular surface V. Prevents corrosion of two dissimilar materials VI. Reduces Noise, Vibration VII. Avoid galvanic corrosion by separating metals VIII. Best die-cut tape to mount various of precision molded parts. | |||

Sample | Free samples & Freight Charges will be returned after deal | |||

Lead time | 15 workdays | |||

Delivery | FOB Shanghai ,CFR,CIF | |||

Payment | L/C or TT, Escrow,e-credit line, Western Union or others | |||

Others | For more information, please send inquiry to us directly. Visit our website to know more about our factory: www.chinahstape.com Visit our Youtube Channel: HS Industrial Tape | |||

Technical Datasheet | ||||

Program | Unit | Value | Test method | |

Total thickness | mm | 1 | Micrometer | |

Temperature | °C | 100 | Thermostat oven | |

Elongation at break | % | 300 | Tensile tester | |

Storage conditions | ||||

Stored at room condition (23°C ± 2°C ) * (55% ± 5% RH) ,avoid direct sunlight valid for 12months | ||||

Tape Structure: | ||||

Tips To Use It

Major Product