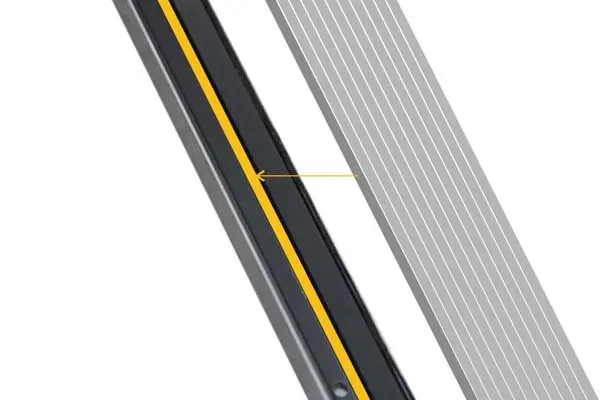

tape PVC tape free sample for LCD backlight

1. CROWN double sided PVC tape has compliant design and manufacturing processes through product lifecycle.

2. The product has the advantage of sliding performance. Coated with marine-grade gel and made of fiberglass materials, it is guaranteed enough smoothness.

3. The product is waterproof. It is completely impervious to water, as a result of receiving special treatment or PVC coating.

4. Whether the motivations are economic, environmental, or personal, the benefits of this product will have something to offer for everyone.

5. Whether the motivations are economic, environmental, or personal, the benefits of this product will have something to offer for everyone.

◔ This product serie uses PET /PVC as the carrier and acrylic adhesive is evenly coated on both sides, and then laminated with release liner or release film. Multiple thickness available from 30μm to 325μm, mainly suitable for the bonding of labels, LCD backlight, LCD panel and other metal frames and components in digital electronics.

◔Flexible carrier material, strong bonding strength for curve, rough surfaces and other similar objects.

◔ Excellent heat resistance and moisture resistance property.

◔ The release liner may be customized upon customer's needs, such as brown glassine paper, white glassine paper and release film, etc.

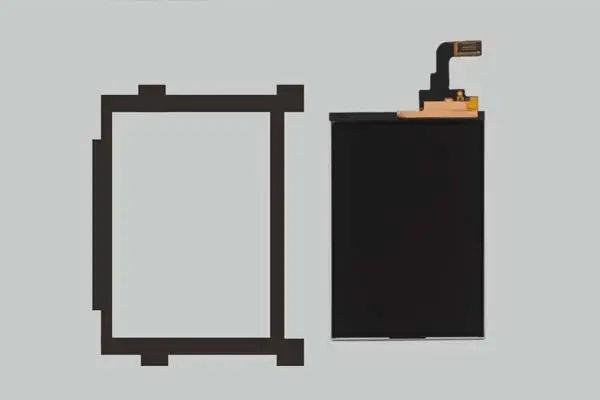

Screen frame fixation

Suggested Model: 7983

Small amount of acrylic adhesive is coated on an ultra thin carrier, good adhesion, easy of die cutting. Suitable for the bonding of labels, LCD,backlight, LCD panels, metal frame and other components of mobile phone.

LCD Frame Fixation

Suggested Model: 7865BT

Reliable bonding effect and excellent masking effect, good bonding for LSE material. It may be used immediately after processing, wide application,such as for heavily-compressed, high-temperature or critical substances.

LED fixation

Suggested Model: 7968

Milky white double coated tape, highly stretchable. Strong adhesion and holding power.

Lens fixation

Suggested Model: 7965M

Red film as release material which enhances the die cutting application. Relatively thick adhesive layer, suitable for bonding of ABS plastic parts in cars, decorative parts of furniture, battery compartment, lens and touch screen of electronic equipment; free from degumming or bending.

| Model | Tape thickness(mic) | Color | Initial Tack(mm) | Peeling Force(N/24mm) | Holding Power(hour) | Temp. Resistance(℃) | Remarks | |||||

79(G) Serie | ||||||||||||

| 7983(G) | 30+/-5 | Transparent | <=150 | >=7 | >=24 | 120 | Ultra thin, good adhesion and excellent die cutting application on smooth surface. | |||||

| 7972(G) | 50+/-5 | Translucent | <=150 | >=8 | >=24 | 120 | Stable adhesion, good for die cutting purpose, especially suitable for foam material bonding and die cutting. | |||||

| 7980(G) | 80+/-5 | Translucent | <=120 | >=10 | >=24 | 120 | ||||||

| 7982(G) | 100+/-5 | Translucent | <=100 | >=12 | >=24 | 120 | Excellent adhesive performance for all kinds of plastic casings and foam materials; good moisture resistance. | |||||

| 7928(G) | 125+/-5 | Translucent | <=100 | >=14 | >=24 | 120 | ||||||

| 7929(G) | 140+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Excellent adhesion, suitable for the bonding of labels, panels, metal frame and other components of mobile phone. | |||||

| 7967(G) | 160+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Flexible, good adhesion of metal, plastic and other materials | |||||

| 7965(G) | 205+/-5 | Translucent | <=100 | >=17 | >=24 | 120 | ||||||

| 7926(G) | 245+/-5 | Translucent | <=100 | >=18 | >=24 | 120 | Strong adhesion; suitable for the bonding of all kinds of nameplates and membrane switch; | |||||

| 7970(G) | 225+/-5 | White | <=100 | >=16 | >=24 | 80 | PVC carrier material, suitable for the bonding of all kinds of component and decorative parts | |||||

| 7969(G) | 245+/-5 | White | <=100 | >=18 | >=24 | 80 | ||||||

| 7968(G) | 325+/-5 | White | <=100 | >=20 | >=24 | 80 | ||||||

79 Red Serie | ||||||||||||

| 7980M | 80+/-5 | Translucent | <=120 | >=10 | >=24 | 120 | Strong adhesion, flexible, suitable for the bonding of furniture accessories, metal sheets, etc. | |||||

| 7982M | 100+/-5 | Translucent | <=100 | >=12 | >=24 | 120 | ||||||

| 7967M | 160+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Strong adhesion, flexible, suitable for the bonding of automobile ABS plastic parts, accessories of furniture, metal sheets, etc. | |||||

| 7965M | 205+/-5 | Translucent | <=100 | >=17 | >=24 | 120 | ||||||

| 7965LM | 205+/-5 | Translucent | <=100 | >=18 | >=24 | 60 | ||||||

69L Serie | ||||||||||||

| 6972L | 50+/-5 | Translucent | <=180 | >=9 | >=24 | 80 | Stronger adhesion than 79 series; suitable for use on multiple kinds of materials. | |||||

| 6980L | 80+/-5 | Translucent | <=180 | >=11 | >=24 | 80 | ||||||

| 6972LE | 50+/-5 | Translucent | <=180 | >=8 | >=24 | 80 | ||||||

78BT(G) / 79TB(G) Serie | ||||||||||||

| 7880BT(G) | 80+/-5 | Black | <=120 | >=9 | >=24 | 120 | Good adhesion, excellent masking effect, suitable for the bonding of components with shading requirement | |||||

| 7882BT(G) | 100+/-5 | Black | <=100 | >=11 | >=24 | 120 | ||||||

| 7828BT(G) | 125+/-5 | Black | <=100 | >=13 | >=24 | 120 | ||||||

| 7829BT(G) | 140+/-5 | Black | <=100 | >=14 | >=24 | 120 | ||||||

| 7867BT(G) | 160+/-5 | Black | <=100 | >=14 | >=24 | 120 | ||||||

| 7865BT(G) | 205+/-5 | Black | <=100 | >=16 | >=24 | 120 | ||||||

| 7883BT(G) | 30+/-5 | Black | <=150 | >=6 | >=24 | 120 | ||||||

| 7872BT(G) | 50+/-5 | Black | <=150 | >=7 | >=24 | 120 | ||||||

Disclaimer: The product technical data are for reference only. Actual performance may differ depending on factors beyond our expectation and control. | ||||||||||||

Company Features

1. Our Electronic Die-cutting Adhesive Tape enjoys a remarkable selling record in many countries and are gaining more and more trust and support from old and new customers.

2. There are many production lines to ensure capacity and strict QC to ensure quality in CROWN ADHESIVE PRODUCTS CO.,LTD..

3. To serve customers better, CROWN has established its own service team. Please contact. CROWN ADHESIVE PRODUCTS CO.,LTD. will always supply high quality PVC tape with professional after-sale service. Please contact. CROWN ADHESIVE PRODUCTS CO.,LTD. aims to offer every customers superior Film tape and satisfying service. Please contact.

Certification:

Our certificate of factory audit report BSCI, SEDEX, WCA, ISO 9001:2008 :