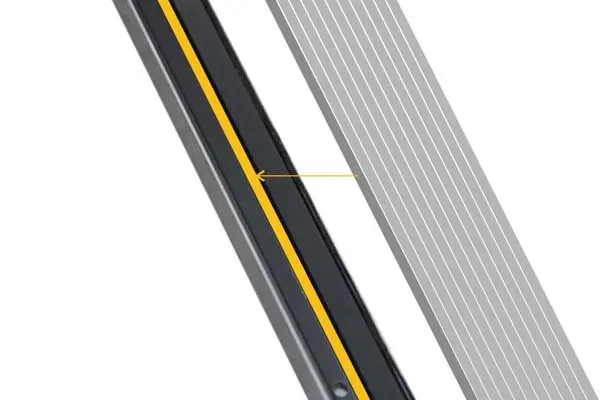

◔ This product serie uses PET /PVC as the carrier and acrylic adhesive is evenly coated on both sides, and then laminated with release liner or release film. Multiple thickness available from 30μm to 325μm, mainly suitable for the bonding of labels, LCD backlight, LCD panel and other metal frames and components in digital electronics.

durable PVC tape diecutting for wholesale for LCD backlight

1. The quality of CROWN adhesive tape manufacturers is guaranteed. It undergoes a field site test to check its sunlight absorptivity, energy storage as well as its energy utilization.

2. The product can perform well in retaining natural color temperatures. A portion of the spectrum was added without affecting the luminous flux, making the color temperature closer to natural light.

3. Apart from physiological benefits, there are very real psychological and social benefits to be gained from the use of this product.

◔Flexible carrier material, strong bonding strength for curve, rough surfaces and other similar objects.

◔ Excellent heat resistance and moisture resistance property.

◔ The release liner may be customized upon customer's needs, such as brown glassine paper, white glassine paper and release film, etc.

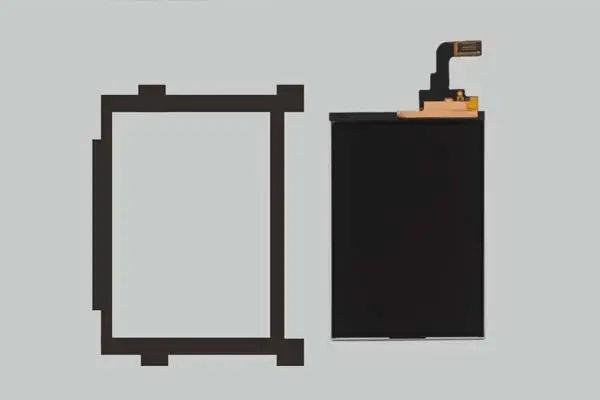

Screen frame fixation

Suggested Model: 7983

Small amount of acrylic adhesive is coated on an ultra thin carrier, good adhesion, easy of die cutting. Suitable for the bonding of labels, LCD,backlight, LCD panels, metal frame and other components of mobile phone.

LCD Frame Fixation

Suggested Model: 7865BT

Reliable bonding effect and excellent masking effect, good bonding for LSE material. It may be used immediately after processing, wide application,such as for heavily-compressed, high-temperature or critical substances.

LED fixation

Suggested Model: 7968

Milky white double coated tape, highly stretchable. Strong adhesion and holding power.

Lens fixation

Suggested Model: 7965M

Red film as release material which enhances the die cutting application. Relatively thick adhesive layer, suitable for bonding of ABS plastic parts in cars, decorative parts of furniture, battery compartment, lens and touch screen of electronic equipment; free from degumming or bending.

| Model | Tape thickness(mic) | Color | Initial Tack(mm) | Peeling Force(N/24mm) | Holding Power(hour) | Temp. Resistance(℃) | Remarks | |||||

79(G) Serie | ||||||||||||

| 7983(G) | 30+/-5 | Transparent | <=150 | >=7 | >=24 | 120 | Ultra thin, good adhesion and excellent die cutting application on smooth surface. | |||||

| 7972(G) | 50+/-5 | Translucent | <=150 | >=8 | >=24 | 120 | Stable adhesion, good for die cutting purpose, especially suitable for foam material bonding and die cutting. | |||||

| 7980(G) | 80+/-5 | Translucent | <=120 | >=10 | >=24 | 120 | ||||||

| 7982(G) | 100+/-5 | Translucent | <=100 | >=12 | >=24 | 120 | Excellent adhesive performance for all kinds of plastic casings and foam materials; good moisture resistance. | |||||

| 7928(G) | 125+/-5 | Translucent | <=100 | >=14 | >=24 | 120 | ||||||

| 7929(G) | 140+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Excellent adhesion, suitable for the bonding of labels, panels, metal frame and other components of mobile phone. | |||||

| 7967(G) | 160+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Flexible, good adhesion of metal, plastic and other materials | |||||

| 7965(G) | 205+/-5 | Translucent | <=100 | >=17 | >=24 | 120 | ||||||

| 7926(G) | 245+/-5 | Translucent | <=100 | >=18 | >=24 | 120 | Strong adhesion; suitable for the bonding of all kinds of nameplates and membrane switch; | |||||

| 7970(G) | 225+/-5 | White | <=100 | >=16 | >=24 | 80 | PVC carrier material, suitable for the bonding of all kinds of component and decorative parts | |||||

| 7969(G) | 245+/-5 | White | <=100 | >=18 | >=24 | 80 | ||||||

| 7968(G) | 325+/-5 | White | <=100 | >=20 | >=24 | 80 | ||||||

79 Red Serie | ||||||||||||

| 7980M | 80+/-5 | Translucent | <=120 | >=10 | >=24 | 120 | Strong adhesion, flexible, suitable for the bonding of furniture accessories, metal sheets, etc. | |||||

| 7982M | 100+/-5 | Translucent | <=100 | >=12 | >=24 | 120 | ||||||

| 7967M | 160+/-5 | Translucent | <=100 | >=15 | >=24 | 120 | Strong adhesion, flexible, suitable for the bonding of automobile ABS plastic parts, accessories of furniture, metal sheets, etc. | |||||

| 7965M | 205+/-5 | Translucent | <=100 | >=17 | >=24 | 120 | ||||||

| 7965LM | 205+/-5 | Translucent | <=100 | >=18 | >=24 | 60 | ||||||

69L Serie | ||||||||||||

| 6972L | 50+/-5 | Translucent | <=180 | >=9 | >=24 | 80 | Stronger adhesion than 79 series; suitable for use on multiple kinds of materials. | |||||

| 6980L | 80+/-5 | Translucent | <=180 | >=11 | >=24 | 80 | ||||||

| 6972LE | 50+/-5 | Translucent | <=180 | >=8 | >=24 | 80 | ||||||

78BT(G) / 79TB(G) Serie | ||||||||||||

| 7880BT(G) | 80+/-5 | Black | <=120 | >=9 | >=24 | 120 | Good adhesion, excellent masking effect, suitable for the bonding of components with shading requirement | |||||

| 7882BT(G) | 100+/-5 | Black | <=100 | >=11 | >=24 | 120 | ||||||

| 7828BT(G) | 125+/-5 | Black | <=100 | >=13 | >=24 | 120 | ||||||

| 7829BT(G) | 140+/-5 | Black | <=100 | >=14 | >=24 | 120 | ||||||

| 7867BT(G) | 160+/-5 | Black | <=100 | >=14 | >=24 | 120 | ||||||

| 7865BT(G) | 205+/-5 | Black | <=100 | >=16 | >=24 | 120 | ||||||

| 7883BT(G) | 30+/-5 | Black | <=150 | >=6 | >=24 | 120 | ||||||

| 7872BT(G) | 50+/-5 | Black | <=150 | >=7 | >=24 | 120 | ||||||

Disclaimer: The product technical data are for reference only. Actual performance may differ depending on factors beyond our expectation and control. | ||||||||||||

Company Features

1. CROWN ADHESIVE PRODUCTS CO.,LTD. is an export-oriented leading enterprise in PVC tape field.

2. We are not the only one company to produce Film tape, but we are the best one in term of quality.

3. Every day, we focus on sustainability practices. From production to customer partnerships, to supporting local charities and employee engagement, we implement sustainability strategies along the entire value chain. We have a clear environmental commitment. We promise that we will eliminate our production waste and reduce carbon dioxide emissions in every stage of our operations. We aim to conduct our production while respecting environmental sustainability. We endeavor to reduce the impact of our own operations through careful selection of materials, reduction of power consumption and recycling.